LOTUS MIXERS Inc.

3449 Technology Drive # 201

North Venice, FL 34275 USA

Anytime, you have a question about mixing, agitator technology or the application for a mixer, please call (941)966-1885, email (info@lotusmixers.com) or use our on-line data sheet.

An American Agitator Company

Better Designs -Best Total Cost of Ownership

Top Entry - SIde Entry - Bottom Entry -Magnetic Drive

Static and Portable Mixers

Main Applications:

- BS &W control of crude oil and condensates

- Fuel Blending

- Homogeneity

- Heat Transfer - Temperature Control

Products Being Mixed:

- Crude Oil

- Asphalt - Bitumen

- Clean Fuels

- Gasoline

- Fuel Oil

- Diesel

- Kerosene

- Ethanol, Biodiesel

- Lubricants

Design Features:

- Belt or Gear Driven

- SF of 2.0+

- Swivel or Fixed Angle Mounting

- Mechanical or manual swivel angle action

- Shaft seal options: double mechanical cartridge seal, single mechanical cartridge seal or stuffing box

- 8 different types of impellers specifically designed for the application

- Modular design

- Face mounted motors (NEMA or IEC)

- Mixers up to 125 HP

- Wetted parts available in carbon steel, 304 stainless steel, 316 stainless steel or 316L stainlless steel

- Standard design includes a tank shut-off with all of our mixers for easy seal replacement

- Offset mounting to allow for low level mixing

LOTUS MIXERS Advantages

- Our gearbox and belt drives are designed to a higher standard than competition with a SF that is 60% greater than what is commonly offered.

- Our gear driven units use face mounted motors - no field adjustment required

- We using SiC/SiC seal faces which is a premium material offering better corrosion reistance and wear protection

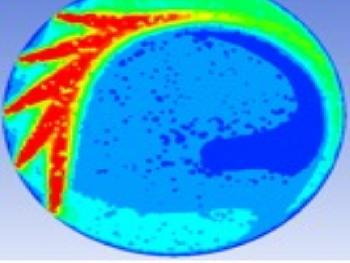

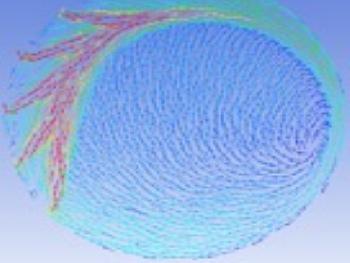

- LOTUS MIXERS optimizes our impeller diameters and pitch to the specific application in lieu of 'off the shelf designs' which provide optimized mixing.

- Our mixers have no in-tank wear parts.

- Our shafts diameters have a 20+% greater cross sectional area vs. competition resulting in less flexing and vibration

There are an addtional 10 points that make our mixers superior to anything else on the market today. Please contact us for additional information.